How AI Reduces Material Waste in the Wrap Industry

Written by

John Cronin

Published on

The vehicle wrap industry thrives on creativity, precision, and craftsmanship. Yet for many wrap shops, one challenge has remained constant: material waste. From incorrect color choices to inaccurate mockups and installation mistakes, wasted vinyl and lamination can quickly cut into margins. As competition increases and material costs continue to rise, shops need a smarter, more reliable way to reduce waste without sacrificing quality or speed.

Artificial intelligence offers the solution. Through advanced visualization, more accurate design workflows, and improved customer decision making, AI tools like wrapmyride.ai help shops cut down on waste, prevent costly rewraps, and improve overall efficiency. AI is already transforming how wraps are sold and installed, but one of its most powerful advantages is its ability to significantly reduce material waste at every stage of the process.

This is the future of sustainable, profitable wrap production.

The Cost of Material Waste in Today’s Wrap Shops

Material waste is more than an operational inconvenience. It impacts profitability, scheduling, labor output, and customer relationships. Even a single rewrap can cost a shop hundreds of dollars in vinyl, lamination, labor hours, and opportunity cost from lost bookings.

Common causes of waste include incorrect color choices based on swatches, misaligned customer expectations, inaccurate mockups, misunderstood design placement, and installation errors resulting from unclear references.

Many of these issues occur long before the installer touches the vehicle. The root problem is often miscommunication or an inability to visualize the final result accurately.

AI powered tools eliminate these issues at the source through clear, photorealistic previews and streamlined communication.

How AI Visualization Reduces Waste Before Installation Begins

The largest portion of material waste happens before installation, when customers are still choosing colors, finishes, and design concepts. Traditionally, shops rely on printed swatches, example photos, or hand created mockups. These methods leave room for interpretation, and customers often misjudge how a color will appear on their vehicle.

AI visualization solves this problem instantly.

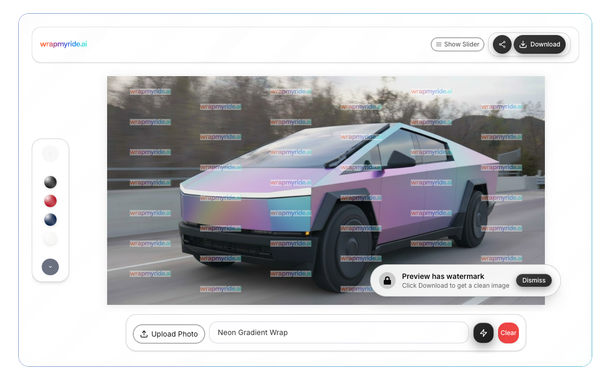

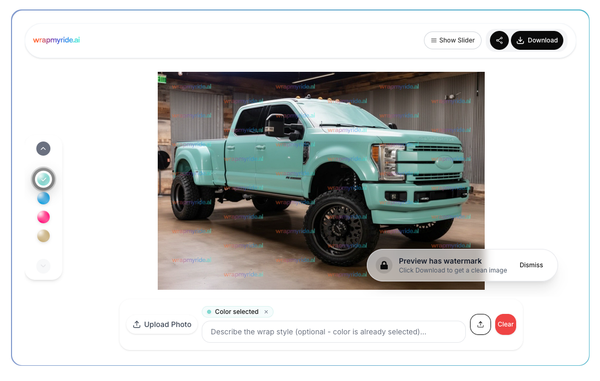

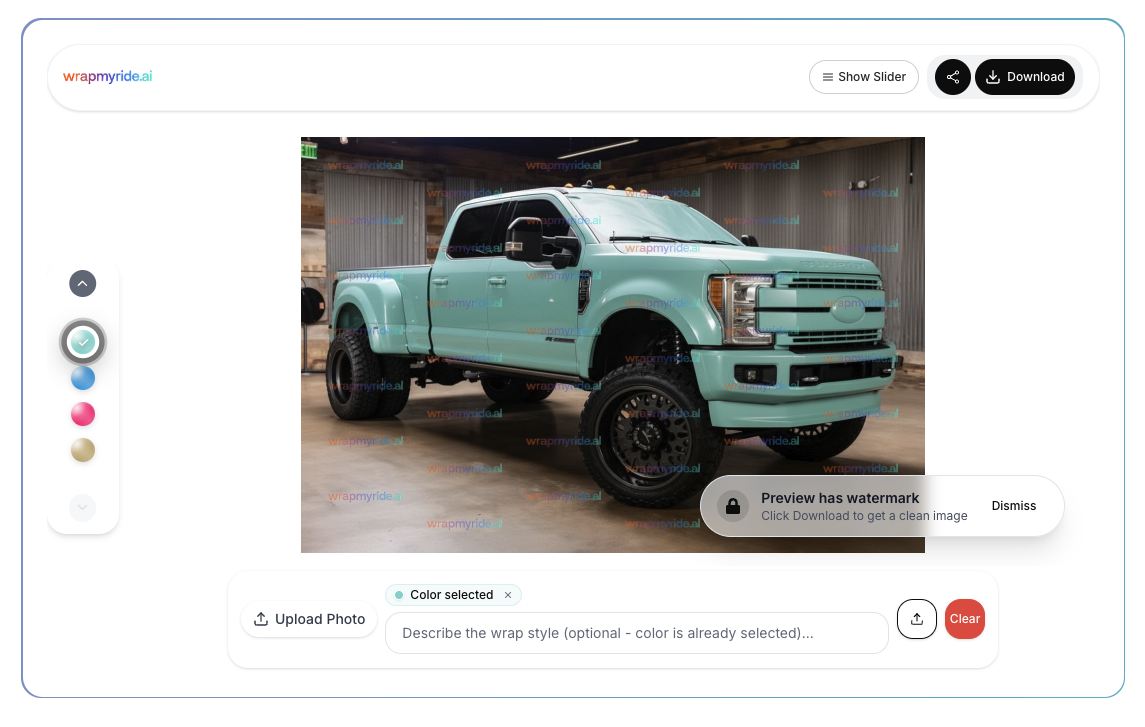

When customers upload a photo to wrapmyride.ai, the AI applies the selected wrap to their exact vehicle with precise lighting, reflections, color depth, and realistic texture representation. Customers no longer guess what matte black or chrome blue will look like. They see the real result immediately.

This eliminates a major cause of waste: wrong color selections that lead to expensive rewraps.

Clear visualization means fewer surprises, fewer revisions, and fewer wasted rolls.

Reducing Rewraps with Accurate Customer Expectations

Rewraps are one of the biggest contributors to wasted vinyl. They happen when customers approve a design concept but reject the installed result because it does not match what they imagined.

AI powered previews remove the uncertainty by showing customers exactly what the installed wrap will look like. The preview aligns expectations and builds confidence so the customer approves with certainty instead of hope.

This alignment protects shops from:

• Misunderstood placements

• Color disagreements

• Finish discrepancies

• Reflection or lighting differences

• Customer remorse

When customers approve a highly accurate AI generated preview, the likelihood of dissatisfaction drops dramatically. Rewraps decrease. Material waste decreases. Shop profitability increases.

How AI Improves Design Accuracy and Prevents Costly Errors

Design errors happen when mockups do not match the vehicle’s true shape or when designers rely on generic templates. These inaccuracies can lead to misaligned graphics, incorrect scaling, and wasted prints.

AI visualizers use intelligent segmentation to map the exact shape, body lines, angles, and contours of the customer’s vehicle. wrapmyride.ai automatically identifies the car body, separates reflections, and simulates lighting far more accurately than any manual method.

This precision ensures that wrap previews and final designs match. Designers no longer waste time adjusting templates, guessing panel widths, or correcting proportions after production.

Accurate designs from the start mean fewer misprints, fewer wasted panels, and more efficient use of materials.

Streamlining Workflows to Prevent Operational Waste

Material waste is not only about vinyl waste. Operational waste occurs when employees spend unnecessary time on tasks that AI can automate. Manual mockups, revisions, color alterations, and customer edits consume hours that could be used for installations, consultations, or production.

AI visualization eliminates these repetitive tasks. Customers adjust designs themselves, reducing the need for designers to create mockups. Sales teams close deals faster because customers approve instantly. Installers receive accurate visuals without needing clarifications.

When the entire workflow becomes more efficient, shops reduce waste in labor, scheduling, and time allocation. AI helps teams redirect effort toward profitable work and away from tasks that drain resources.

Preventing Printing Mistakes Through AI Assisted Clarity

Printing mistakes often stem from poorly communicated instructions, misunderstood color selections, or unclear references. AI generated previews give printers a clear visual source to work from, reducing interpretation errors.

When installers and printers receive accurate previews, they eliminate common mistakes such as printing the wrong finish type, misaligning panel placements, producing incorrect color values, or designing graphics that do not scale.

AI powered previews become the single source of truth for every stage of production. Printers know exactly what to produce and installers know exactly how the wrap should look when finished.

This clarity prevents mistakes that lead to wasted vinyl rolls and reprints.

Enhancing Inventory Management with Predictive Insights

Inventory mismanagement causes a different kind of waste. Shops often over order or under order materials because they do not have reliable data about customer preferences. AI helps solve this problem by identifying patterns and trends in user behavior.

For example, wrapmyride.ai can reveal insights such as which colors are chosen most often, which materials customers preview frequently, which finishes generate the most engagement, which vehicle types are most common among customers, and which styles convert into the highest number of bookings.

These insights enable shops to make smarter inventory decisions, order efficiently, reduce overstock and prevent shortages, minimize aged inventory waste, and improve profitability through predictive planning.

AI empowered inventory forecasting reduces waste both financially and materially.

Improving Customer Decision Making to Reduce Unnecessary Orders

Customers often struggle to choose between multiple designs, colors, or finish types. In some cases, this indecision leads shops to produce multiple samples or print test pieces that eventually go unused.

AI interactive visualizers encourage customers to experiment digitally. They can test dozens of variations quickly without requiring physical samples or printed swatches.

This digital decision process eliminates unnecessary sample prints, preserves premium material, and helps customers reach a decision without consuming resources.

When customers feel empowered and informed, they choose with confidence, reducing the need for extra material production.

Reducing Waste Through Early Upsell Clarity

Upsells are more profitable when the customer can visualize the full design package at the start.

With AI visualization, customers preview:

• Two tone wraps

• Accent packages

• Roof wraps

• Mirror caps

• Stripe kits

• Partial wraps

• Window tint combinations

• PPF add ons

By previewing these options digitally, customers understand exactly what each upgrade offers. This reduces mistakes from miscommunication or misunderstandings about placement and size.

Accurate upsells mean fewer incorrect prints, fewer revision cycles, and less waste during production.

How AI Supports Sustainability in the Wrap Industry

The wrap industry relies heavily on PVC based materials, adhesives, and protective laminates. Reducing waste is essential for creating a more sustainable business model. AI contributes to this sustainability by helping shops use fewer materials overall, eliminating rewraps caused by misunderstandings, supporting digital decision making instead of printed samples, and improving accuracy during production.

As more customers prioritize environmentally responsible businesses, wrap shops using AI gain a competitive advantage by reducing waste and adopting modern, sustainable practices.

The Future of Waste Reduction with AI Technology

AI technology is advancing rapidly, and future upgrades will reduce waste even further. Upcoming innovations include augmented reality visualization to eliminate uncertainty during consultations, predictive color recommendations to reduce trial and error, multi angle 3D previews to eliminate perspective based miscommunication, AI generated custom wrap patterns optimized for material use, and automated print layout optimization to reduce vinyl offcuts.

AI will play a critical role in creating a more efficient, profitable, and environmentally conscious wrap industry. Shops adopting AI early will benefit the most as these innovations become industry standards.

Key Takeaways: How AI Reduces Material Waste in Wrap Shops

- AI powered visualization eliminates incorrect color choices.

- Accurate previews reduce costly rewraps and redo projects.

- AI improves design accuracy and prevents scaling errors.

- Automated workflows reduce operational waste and save time.

- Digital previews eliminate unnecessary sample prints.

- AI insights improve inventory planning and purchasing decisions.

- Accurate upsells reduce printing mistakes and miscommunication.

- Overall AI adoption leads to more sustainable and profitable wrap shops.

Reduce Waste, Save Money, and Transform Your Workflow

Wrap shops that want to stay competitive must reduce waste, increase efficiency, and deliver a clearer customer experience. AI powered visualization is the most effective way to achieve all three. It gives customers confidence, protects profit margins, and ensures a smoother, more accurate production process.

Start reducing material waste and maximizing profitability with wrapmyride.ai.

Experience the future of efficient wrap production at wrapmyride.ai.

FAQ

How does AI reduce vinyl waste in wrap shops

AI provides accurate previews that prevent incorrect color choices, unexpected outcomes, and rewraps. This reduces the amount of vinyl used for corrections or replacements.

Can AI prevent installation mistakes

Yes. By creating clear previews, installers know exactly how the wrap should look. This prevents misalignment, incorrect panel placement, and unnecessary reprints.

Does AI help shops save money on materials

Absolutely. Reducing rewraps, misprints, and sample production results in significant long term savings for wrap shops.

Is AI difficult to integrate into existing workflows

No. wrapmyride.ai requires no technical experience. Shops can add it to their workflow or embed it on their website easily.

Does AI reduce waste for both full wraps and partial wraps

Yes. AI visualization helps clarify expectations for any wrap type including full, partial, commercial, accent, and specialty wraps.

Sign up for our newsletter

Get the latest tips, trends, and insights delivered straight to your inbox.